Soap Noodles Plant

Price 500000.00 INR/ Piece

Soap Noodles Plant Specification

- Type

- Automatic

- Material

- Stainless Steel

- Capacity

- 35 Ton/Hour

- Detergent Type

- Soap Noodles

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Controlled

- Machine Type

- Soap Noodles Plant

- Voltage

- 415 V

- Power

- 85 kW

- Weight

- 8000 kg

- Color

- Grey & Silver

- Dimension (L*W*H)

- 12000 mm x 3500 mm x 4000 mm

- Water Consumption

- Low

- Heating System

- Electric / Steam

- Output Form

- Solid, Noodles

- Feed Stock

- Fatty Acid, Palm Oil, Coconut Oil

- Installation Support

- On-site Installation & Commissioning

- Safety Features

- Overload protection, emergency stop

- Production Efficiency

- High efficiency continuous operation

- Operation Temperature

- 8090C

- Noise Level

- <75 dB

- Application

- Industrial soap production

- Process Stages

- Saponification, Vacuum Drying, Mixing

- Maintenance

- Easy access for cleaning and servicing

Soap Noodles Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Week

- Delivery Time

- 20 Days

About Soap Noodles Plant

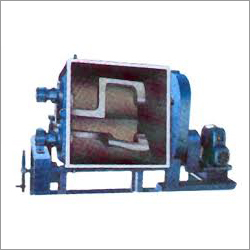

Our vision to excel and establish a strong foothold in the market has assisted us to evolve as a prominent manufacturer and supplier of Soap Noodles Plant. This machine can perform vacuum spraying and drying operations. We manufacture this plant under the firm guidance of expert supervisors using high quality mild steel and cast iron. This plant is mainly used for making soap noodles for detergent industry. Clients can avail our Soap Noodles Plant in different technical specifications as per their requirements.

Features:

- Consumes low power

- Robust construction

- Maintenance free

Advanced Automation and High Efficiency

Built as a fully automated system with PLC controls, this soap noodles plant ensures precise operation and continuous, high-efficiency production. Automation reduces labor requirements and maintains consistency, while the computerized interface streamlines monitoring and adjustments.

Robust Construction and Safety Features

The plant is constructed from stainless steel for longevity and resistance to corrosion. Safety is prioritized through overload protection and emergency stop functions, ensuring safe operations for factory personnel and minimizing the risk of process interruptions.

User-Friendly Maintenance and Installation

With easy access for cleaning and servicing, regular maintenance is simple and quick. On-site installation and commissioning support is provided, ensuring a smooth startup and user training to optimize plant performance.

FAQs of Soap Noodles Plant:

Q: How does the Soap Noodles Plant operate, and what are its main process stages?

A: The plant functions through fully automated saponification, vacuum drying, and mixing processes. Raw materials such as fatty acids, palm oil, or coconut oil are converted into solid soap noodles through controlled heating (8090C) and efficient continuous operation, all managed by a PLC system.Q: What are the installation and commissioning support options offered?

A: On-site installation and commissioning support is provided by our technical team. This includes setup, start-up assistance, system calibration, and training for your staff to ensure the plant operates efficiently and safely from day one.Q: When is the plant suitable to use, and what production capacity can it handle?

A: This plant is ideal for industrial-scale soap production where high efficiency and consistent output are required. It is designed to produce 3 to 5 tons of soap noodles per hour, making it suitable for continuous, large-batch operations.Q: Where can this soap noodles plant be utilized?

A: The plant is primarily intended for use in industrial soap manufacturing facilities. Its robust design and automation make it suitable for both new installations and as an upgrade for existing production lines across India and beyond.Q: What are the key benefits of using this soap noodles plant?

A: Key advantages include high production efficiency, low water consumption, noise levels below 75 dB, straightforward maintenance, and advanced safety features. Its stainless steel build and automatic controls contribute to reliability and product quality.Q: How does the plant ensure safety and ease of maintenance?

A: Safety is maintained through integrated overload protection and emergency stop functions. The design allows easy access for cleaning and regular servicing, minimizing downtime and extending equipment life.Q: What feedstocks can be used, and what is the output form?

A: The plant is compatible with fatty acid, palm oil, and coconut oil as raw materials. The output is in the form of solid soap noodles, ready for downstream processing or packaging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Detergent Machine Category

Soap Wrapping Machine

Price 300000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Control System : Other, PLC Controlled

Material : Stainless Steel

Computerized : No

Voltage : 220240 V, 50/60 Hz

Detergent Machine

Price 80000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Control System : Other, Panel Board

Material : Mild Steel

Computerized : No

Voltage : 220 V

Detergent Making Machine

Price 80000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Control System : Other, Manual / PLC Based

Material : Stainless Steel

Computerized : No

Voltage : 220/380 V

Sigma Mixer

Price 280000.00 INR

Minimum Order Quantity : 1 Unit

Control System : Other, Manual / PLC Based

Material : Mild Steel / Stainless Steel

Computerized : No

Voltage : 415 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese