Powder Filling Machine

Powder Filling Machine Specification

- Type

- Volumetric Powder Filler

- Material

- Stainless Steel 304

- Capacity

- 10 gm to 1000 gm / Per Fill

- Detergent Type

- Powder

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Based Control Panel

- Machine Type

- Semi-Automatic Powder Filling Machine

- Voltage

- 220/240 V AC, Single Phase

- Power

- 1.5 kW

- Weight

- Approx. 220 Kg

- Color

- Stainless Steel/Silver

- Dimension (L*W*H)

- 900 mm x 800 mm x 1800 mm

- Filling System

- Auger Screw

- Application

- Powder filling for food, pharmaceutical, chemical, cosmetic industries

- Air Consumption

- 0.1-0.4 m³/min, 6 bar

- Contact Parts

- Food Grade Stainless Steel

- Filling Accuracy

- ±1%

- Production Speed

- 15-25 fills/min (Depends on powder type and pouch size)

- Feeding Mode

- Automatic/Manual as per requirement

- Filling Range

- 10 g to 1000 g

- Machine Finish

- Matt / Mirror Polished

- Hopper Volume

- 25-40 Liters (Model dependent)

- Display

- Touch Screen HMI

- Sealing System

- Optional Heat Sealing

Powder Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Week

- Delivery Time

- 20 Days

About Powder Filling Machine

Our in-depth knowledge and industrial expertise has enabled us to emerge as a reputed manufacturer and supplier of Powder Filling Machine. This machine is used for filling HDPE and LDPE pouches and bags with powder materials. We manufacture this machine with the help of our skilled workforce using best quality mild steel and stainless steel. Powder Filling Machine is used in detergent, fertilizer, chemical and food industry. We make available this Powder Filling Machine for clients in different specifications as per their requirements.

Features:

- Easy to install

- Longer service life

- Requires less maintenance

Precision & Flexibility for Powder Packaging

Engineered to deliver reliable filling from 10 g up to 1000 g per cycle, this powder filling machine accommodates a diverse range of pouch sizes and powder types. Its volumetric auger screw system ensures 1% filling accuracy, making it particularly suitable for sensitive industries requiring strict quality control. Flexible feeding options and optional heat sealing enable easy adaptation to evolving packaging needs and production volumes.

User-Friendly Operation & Durable Design

With a PLC-based control panel and touch screen HMI, operators experience effortless configuration and real-time monitoring. The semi-automatic design allows for hands-on oversight without sacrificing productivity, while food-grade stainless steel construction and a choice of matt or mirror polish deliver hygiene and easy cleaning. The robust configuration is built to withstand demanding industrial environments.

FAQs of Powder Filling Machine:

Q: How is the powder filling process conducted using this machine?

A: The powder is loaded into the stainless steel hopper and automatically measured by the auger screw system. The filling process is triggered via the touchscreen HMI, accurately dispensing the set dosage (10 g to 1000 g) into containers or pouches. Depending on requirements, feeding can be manual or automatic, and heat sealing is available as an option.Q: What types of powders can the machine handle?

A: This machine is suitable for a variety of free-flowing and semi-free-flowing powders, including food ingredients, pharmaceutical powders, chemicals, and cosmetic powders such as talc and detergent. Its contact parts made from food grade stainless steel ensure safe operations across different industries.Q: When should the hopper be refilled during operation?

A: The hopper should be refilled when the powder level decreases to ensure consistent filling performance. The 25 to 40-litre capacity (depending on model) allows for moderate batch sizes before refilling is needed, which can be visually monitored through the hopper opening.Q: Where can this powder filling machine be installed and used?

A: This semi-automatic powder filling machine is designed for production facilities in the food, pharmaceutical, chemical, and cosmetic sectors. Its compact footprint (900 mm x 800 mm x 1800 mm) allows for installation in standard factory spaces across India and globally.Q: What are the main benefits of using this machine compared to manual filling?

A: Key advantages include high filling accuracy (1%), faster output (1525 fills/min), reduced powder wastage, improved product hygiene, and compliance with industry standardsthanks to food-grade stainless steel and PLC-based controls. Operators gain efficiency and product consistency with less physical effort.Q: How do I select the correct settings for different powder types and pouch sizes?

A: Settings are easily adjusted via the touchscreen HMI. Operators can set the desired fill weight, production speed, and select feeding mode (automatic or manual). The machines auger screw system adapts to various powder properties, ensuring optimal performance across product lines.Q: What maintenance is required to keep the machine operating efficiently?

A: Routine cleaning of hopper and auger parts, periodic inspection of seals, and regular lubrication of moving components are recommended. Stainless steel construction makes cleaning straightforward, while the user manual provides detailed maintenance schedules and procedures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Detergent Machine Category

Detergent Making Machine

Price 80000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Color : Blue & Silver

Voltage : 220/380 V

Computerized : No

Material : Stainless Steel

Detergent Machine

Price 80000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Color : Sky Blue and Silver

Voltage : 220 V

Computerized : No

Material : Mild Steel

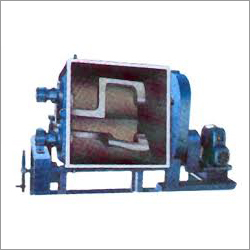

Sigma Mixer

Price 280000.00 INR

Minimum Order Quantity : 1 Unit

Color : Blue & Metallic Grey

Voltage : 415 V

Computerized : No

Material : Mild Steel / Stainless Steel

Detergent Powder Making Plant

Price 80000.00 INR

Minimum Order Quantity : 1 Unit

Color : Silver & Blue (As Per Image)

Voltage : 380 V

Computerized : No

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese