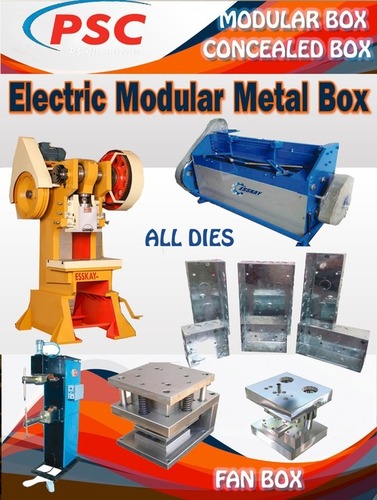

Fan Box Making Machine

MOQ : 1 Piece

Fan Box Making Machine Specification

- Product Type

- Fan Box Making Machine

- General Use

- Sheet Metal Box Manufacturing

- Material

- Mild Steel

- Capacity

- 120-150 boxes per hour

- Weight (kg)

- 950 kg

- Type

- Automatic Sheet Metal Forming

- Box size

- Up to 110 mm diameter (customizable)

- Function

- Fan box fabrication

- Computerized

- No

- Automatic

- Yes

- Drive Type

- Electric motor driven

- Power

- 3 HP

- Voltage

- 220 V / 380 V

- Dimension (L*W*H)

- 2100 x 900 x 1400 mm

- Feature

- Robust construction, Easy Operation, Low Maintenance

- Color

- Blue & Silver

- Mould Change

- Quick-change die system

- Lubrication

- Automatic oil lubrication

- Cutting Method

- Hydraulic/Pneumatic

- Finished Box Type

- Ceiling Fan Junction Box

- Production Speed

- Variable (adjustable with control)

- Sheet Thickness Range

- 0.5 - 1.2 mm

- Application

- Electrical Fitting Box Manufacturing

- Safety System

- Emergency stop, Safety cover

- Operation Mode

- Foot switch & panel control

- Power Consumption

- Low

- Control System

- Semi-automatic panel

- Surface Finish

- Powder Coated

- Noise Level

- 75 dB

Fan Box Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Week

- Delivery Time

- 20 Days

About Fan Box Making Machine

Unlock grandiose productivity with our semi-automatic Fan Box Making Machine, celebrated for its favorable reviews and excellent value. Featuring a robust build and valiant engineering, this machine utilizes a hydraulic/pneumatic cutting method and a quick-change die system, making it adaptable for various box sizes up to 110 mm diameter. Its variable production speed, low noise (<75 dB), and automatic lubrication enable seamless operation for manufacturing electrical fitting boxes. Designed for low maintenance, low power consumption, and high safety, this is an invaluable asset for sheet metal box manufacturers in India.

Competitive Edge: Boosting Box Manufacturing Excellence

Our Fan Box Making Machine offers primary advantages such as rapid mould changes, variable speed control, and low operational noise. Its sturdy construction ensures prolonged durability while the semi-automatic panel simplifies operation. Specifically tailored for manufacturing ceiling fan junction boxes, it is equally suited for other general sheet metal box applications. Take control of efficiency, safety, and output in your production process with this reliably engineered, value-driven solution.

Assurances: Certifications, Packaging, and Sample Policy

This machine meets industry standards, ensuring reliable quality and favorable performance ratings. Each unit is securely packed using reinforced materials and delivered via trusted freight carriers across India at competitive rates. Drop-off and on-site installation options are available, subject to location. Sample inspection policies are in place for discerning buyers to evaluate performance prior to large orders, providing confidence in your purchase decision.

Competitive Edge: Boosting Box Manufacturing Excellence

Our Fan Box Making Machine offers primary advantages such as rapid mould changes, variable speed control, and low operational noise. Its sturdy construction ensures prolonged durability while the semi-automatic panel simplifies operation. Specifically tailored for manufacturing ceiling fan junction boxes, it is equally suited for other general sheet metal box applications. Take control of efficiency, safety, and output in your production process with this reliably engineered, value-driven solution.

Assurances: Certifications, Packaging, and Sample Policy

This machine meets industry standards, ensuring reliable quality and favorable performance ratings. Each unit is securely packed using reinforced materials and delivered via trusted freight carriers across India at competitive rates. Drop-off and on-site installation options are available, subject to location. Sample inspection policies are in place for discerning buyers to evaluate performance prior to large orders, providing confidence in your purchase decision.

FAQs of Fan Box Making Machine:

Q: How does the Fan Box Making Machine accelerate the manufacturing process?

A: The machine features a quick-change die system and variable speed control, allowing manufacturers to rapidly switch box sizes and adjust production rates, increasing efficiency and throughput.Q: What is the primary usage of this Fan Box Making Machine?

A: This machine is designed specifically for fabricating ceiling fan junction boxes and is also suitable for general sheet metal box manufacturing in electrical fitting industries.Q: Where can this machine be installed and what are the spatial requirements?

A: Suitable for workshops and manufacturing floors, the machine requires an installation space of 2100 x 900 x 1400 mm to ensure secure setup and smooth operation.Q: What safety features are incorporated in the design?

A: The machine includes an emergency stop function and safety cover, ensuring operator protection during use and immediate halting of operation in case of unexpected issues.Q: When is maintenance required and how is it managed?

A: Thanks to its automatic oil lubrication and robust construction, the machine requires minimal maintenance. Routine checks are recommended, but overall upkeep is straightforward and infrequent.Q: How does the shipment and sample process work?

A: Machines are shipped via reliable freight options with drop-off and installation services available depending on location. Sample inspection is provided to evaluate machine performance before placing large orders.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Box Making Machine Category

MS Modular Box Making Machine

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 12001500 pieces/hour

Feature : Other, High durability, Corrosion resistant, Easy operation, Precision engineering

General Use : Electrical Box Manufacturing

Material : Other, Mild Steel (MS)

Modular Electrical Box

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Suitable for 112 module plates (as per model variant)

Feature : Other, Rustproof, shock resistant, easy installation, flame retardant

General Use : Electrical wiring, modular switch and socket mounting

Material : Other, Highgrade polycarbonate / PVC

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese