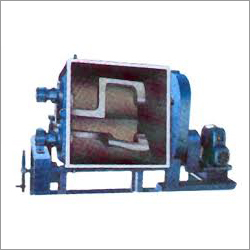

Cage Mill Mixer

Cage Mill Mixer Specification

- Type

- Industrial Mixer

- Material

- Mild Steel

- Capacity

- 500 Kg/hr

- Detergent Type

- Powder

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Machine Type

- Cage Mill Mixer

- Voltage

- 415 V

- Power

- 5 HP

- Weight

- Approx. 600 Kg

- Color

- Blue & Silver

- Dimension (L*W*H)

- 1600 mm x 800 mm x 1800 mm

- Feeding Size

- Up to 25 mm

- Safety Features

- Overload Protection

- Mixer Speed

- 1200 RPM

- Blades

- 4 Sets Alloy Steel

- Surface Finish

- Painted & Polished

- Mobility

- Fixed Installation

- Cage Mill Diameter

- 450 mm

- Application

- Detergent Powder Mixing

- Noise Level

- <80 dB

- Discharge Size

- Less than 1 mm

Cage Mill Mixer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Week

- Delivery Time

- 20 Days

About Cage Mill Mixer

We have earned our name as a renowned manufacturer and supplier of Cage Mill Mixer. In this machine the lumps which are over sized are broken into small and finer pieces and then transferred to the next level. We manufacture this machine under the firm guidance of expert supervisors using high quality mild steel and cast iron. This mill is used for mixing and grinding powdered materials in detergent and cosmetic industry. We make available this Cage Mill Mixer for clients in different specifications as per their requirements.

Features:

- Rugged construction

- Easy to operate

- Noise free performance

Precision Mixing for Detergent Powders

Engineered for the detergent industry, the Cage Mill Mixer ensures uniform mixing with its four sets of alloy steel blades rotating at 1200 RPM. This precision leads to high product quality, suitable for large-scale detergent powder production, while its robust build ensures long-lasting performance in demanding environments.

Efficient and Safe Operation

The mixer is designed not only for productivity but also for operational safety, featuring overload protection to guard both the equipment and operator. Its noise level remains under 80 dB, creating a safer and more comfortable working environment. The fixed installation design minimizes vibration, providing enhanced stability during continuous operation.

FAQs of Cage Mill Mixer:

Q: How does the Cage Mill Mixer achieve fine discharge sizes in detergent powder mixing?

A: The Cage Mill Mixer employs four sets of alloy steel blades spinning at 1200 RPM within a 450 mm diameter cage. This vigorous mixing action breaks down feed material up to 25 mm in size, producing a discharge size of less than 1 mm, resulting in a consistently fine detergent powder.Q: What are the main benefits of using a Cage Mill Mixer for detergent powder manufacturing?

A: This mixer ensures uniform particle size, efficient blending, and high throughput (500 kg/hr), while maintaining low noise levels and integrated safety features such as overload protection. Its robust mild steel construction ensures durability and reliability in industrial environments.Q: When should the Cage Mill Mixer be chosen over other types of industrial mixers?

A: The Cage Mill Mixer is ideal when precise, high-capacity, and fine particle blending of powder materials is requiredparticularly in detergent powder production where uniformity and throughput are priorities. Its semi-automatic and low-maintenance design make it suitable for continuous, large-scale operations.Q: Where is the Cage Mill Mixer typically installed and used?

A: This industrial mixer is usually fixed in place within detergent manufacturing plants or powder-processing facilities in India and globally. Its durable structure and stable installation allow it to perform efficiently in demanding industrial environments.Q: What is the general process for operating the Cage Mill Mixer?

A: The operator manually feeds the powder material (up to 25 mm in size) into the mixer. Once started, the machine, powered by a 5 HP motor at 415 V, blends the material with its fast-rotating blades. The mixed powder, now reduced to less than 1 mm in size, is discharged for further processing or packaging.Q: How can users ensure the safe and optimal use of the Cage Mill Mixer?

A: Users should adhere to the recommended feeding size, perform regular maintenance, and utilize overload protection features to safeguard the equipment. Operating within the specified voltage and power requirements will ensure optimal performance and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Detergent Machine Category

Sigma Mixer

Price 280000.00 INR

Minimum Order Quantity : 1 Unit

Material : Mild Steel / Stainless Steel

Control System : Other, Manual / PLC Based

Color : Blue & Metallic Grey

Voltage : 415 V

Detergent Mixing Machine

Price 80000.00 INR

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Control System : Other, Manual

Color : Blue and White

Voltage : 220380 Volt

Detergent Powder Making Plant

Price 80000.00 INR

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Control System : PLC Control

Color : Silver & Blue (As Per Image)

Voltage : 380 V

Soap Making Plant

Price 280000.00 INR

Minimum Order Quantity : 1 Unit

Material : Stainless Steel (Grade SS304/SS316)

Control System : Other, PLC Based Control Panel

Color : Blue and Silver

Voltage : 380V / 440V, 50HZ

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese